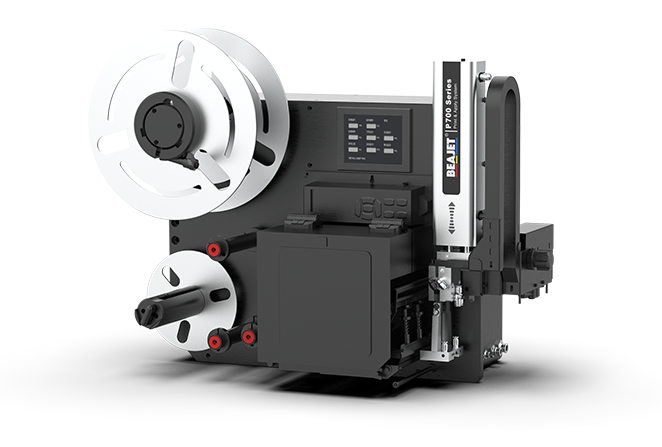

Structural introduction

1. Touch screen: Simple touch operation, quickly adjust the equipment parameters

2. Putting drive: 76mm inner diameter, maximum label diameter 300mm

3. Printing engine: optional zebra or TSC engine

4. The feed panel: You can freely adjust the tension of the feed disk to achieve more stable bidding and obtaining papers

5. Touch screen

6. U -type bracket installation position: Realize multi -angle labeling and multiple installation methods, standardized label fixed positioning, can achieve the same host with different labeling arm to achieve different labeling functions and label requirements requirements.

7.trachea interface

8.7pin communication interface: use fast insert interface to facilitate the fast replacement of the bid arm, installation

2. Putting drive: 76mm inner diameter, maximum label diameter 300mm

3. Printing engine: optional zebra or TSC engine

4. The feed panel: You can freely adjust the tension of the feed disk to achieve more stable bidding and obtaining papers

5. Touch screen

6. U -type bracket installation position: Realize multi -angle labeling and multiple installation methods, standardized label fixed positioning, can achieve the same host with different labeling arm to achieve different labeling functions and label requirements requirements.

7.trachea interface

8.7pin communication interface: use fast insert interface to facilitate the fast replacement of the bid arm, installation

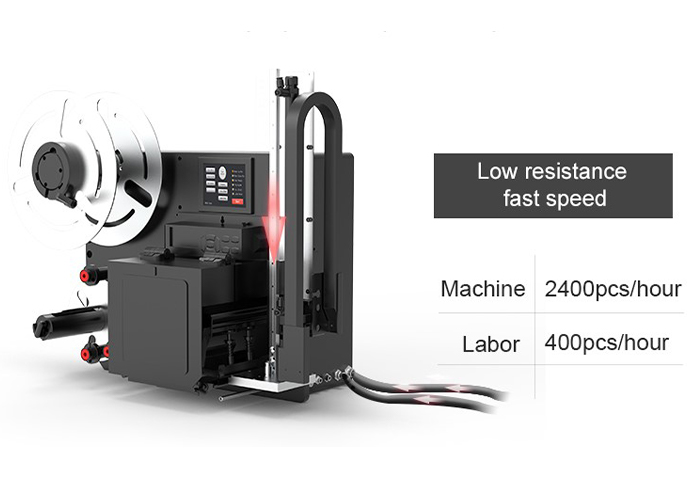

High -speed durable

Adopt aerodynamic technology, 7*24 hours of continuous work does not heat up, components are not losing, and the machine service life is longer

Manual treatment of 400 pieces per hour, using this machine to reach 2400 per hour, and the work efficiency is 6 times

Manual treatment of 400 pieces per hour, using this machine to reach 2400 per hour, and the work efficiency is 6 times

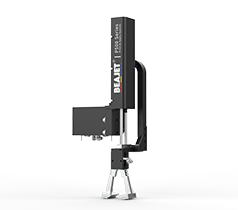

High extensibility

1. Eight types of labeling arm can be combined freely. For companies that produce different forms of products, the modular design only needs to replace the label arm.You do not need to customize the whole machine, and you can also switch between different businesses, so that the time of delivery is shorter. (Of course special requirements support customization design.)

2. The structure is compact, the shape is small, and the 360 -degree rotation is adjusted to meet the needs of different labeling position. It can be used by a stand -alone machine or integrated to the production line.

2. The structure is compact, the shape is small, and the 360 -degree rotation is adjusted to meet the needs of different labeling position. It can be used by a stand -alone machine or integrated to the production line.

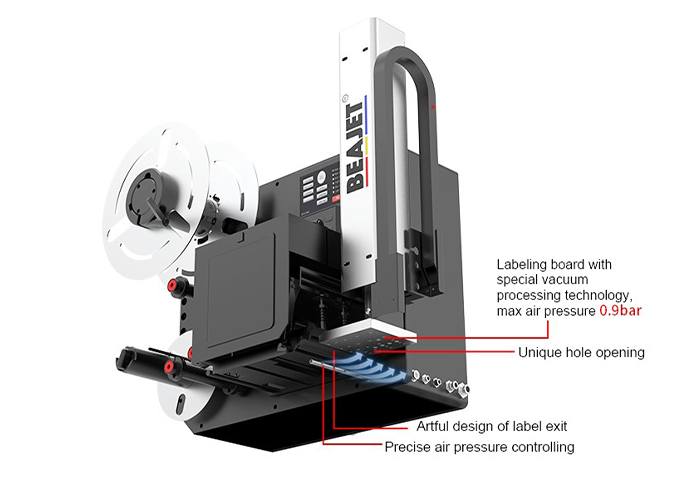

Stable and reliable

1. Adopt industrial -grade design schemes, stable performance, the machine work process does not crash, does not get stuck, does not leak paper, etc. to ensure that the machine is stable for 24 hours and continuous work

2. PLC control, not subject to external interference, strong reliability, fast processing speed, the fastest execution speed instruction is 0.35us

2. PLC control, not subject to external interference, strong reliability, fast processing speed, the fastest execution speed instruction is 0.35us

Intelligent control

Integrated labeling action control and print data processing

No need to be manually defensive, easily achieve automatic machinery operation, improve work efficiency, thereby reducing production costs

No need to be manually defensive, easily achieve automatic machinery operation, improve work efficiency, thereby reducing production costs

Print support

1. Support multiple formats. Users can customize label templates, barcodes, text, pictures, and change data sources, so that the labeling of the user is not restrained by the print content.

2. High printing accuracy, you can achieve 600dpi printing

2. High printing accuracy, you can achieve 600dpi printing

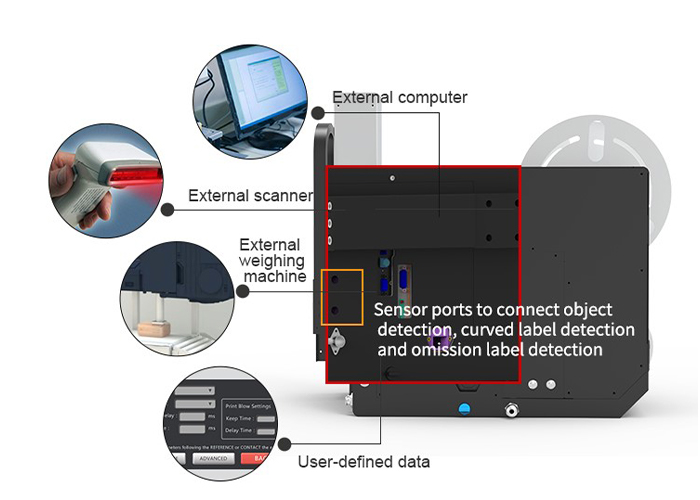

Interface Description

1. pressure regulating valve

2. Engine power interface

3. Ethernet interface: 10/100 mbit/s

4. 7pin interface: IO point interface

5, 4pin interface: source interface

6, 2PIN interface: 485 serial communication communication

7. USB2.0 high -speed interface: special PC

2. Engine power interface

3. Ethernet interface: 10/100 mbit/s

4. 7pin interface: IO point interface

5, 4pin interface: source interface

6, 2PIN interface: 485 serial communication communication

7. USB2.0 high -speed interface: special PC