Easy to operate

Learn it once, no training required.

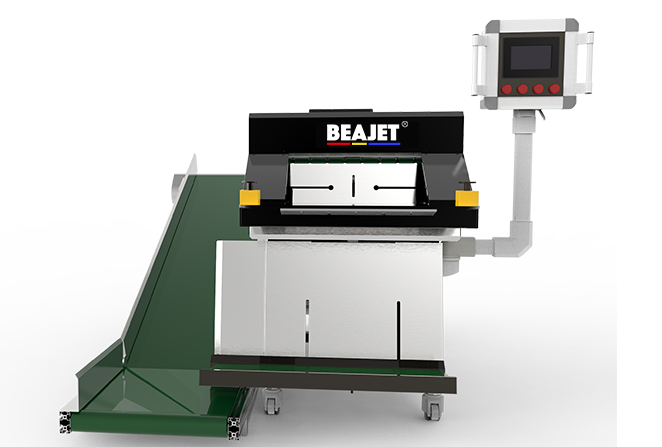

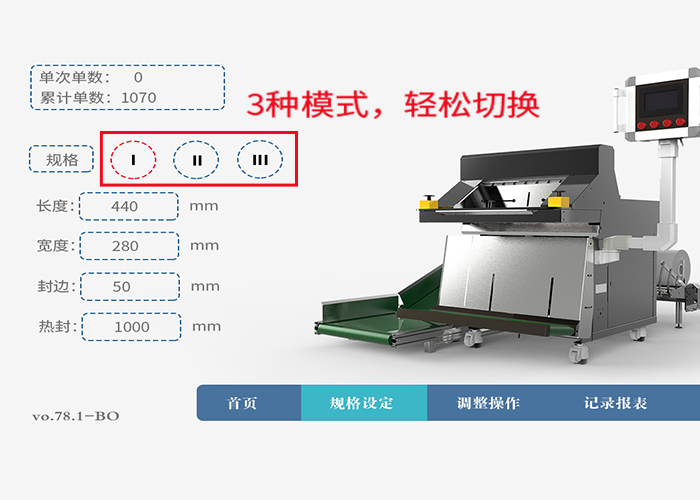

Visual touch screen

Convenient for setting parameters such as material thickness, length, time, etc., and with a counter, it is convenient for users to open up new operating modes.

Data memory function

Data memory function, record the length of commonly used bags, one-click switching.

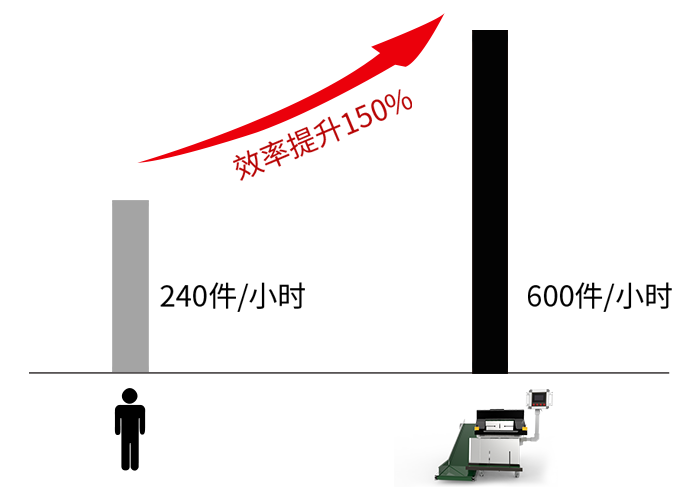

High efficiency

Adopting ergonomic design, carefully selecting each component;

Comparison of human-machine efficiency, efficiency increased by 150%;

Sato printer (printer can be equipped with other options)

Printing speed 254mm/s;

High-speed transmission

Dual motor coordinated feeding is efficient and error-free, with a feeding speed of 400mm/s;

Integrated desktop

Save 3 seconds for the packaging of each item, with the function of transferring goods, gifts, and accessories.

Stable

Brand components, exquisite details;

Quality is guaranteed, and performance is more stable.

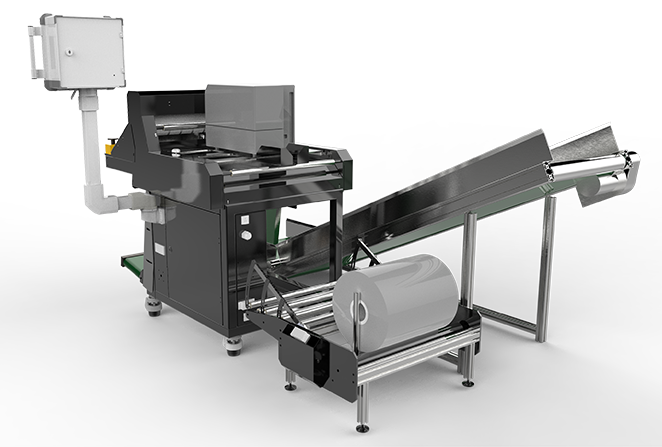

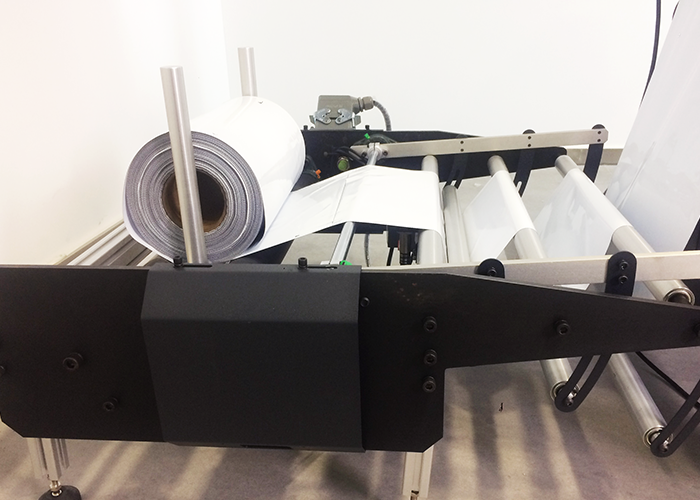

S-shaped structure material storage module

The perfect detection and feedback system, hybrid servo drive control, torque feedback, ensure that the bag is torn off, straight, wrinkle-free and works in an orderly manner;

The sensor can accurately detect the length of the material discharge, trigger the stop of the material discharge and open the mouth, wave-shaped seal, more solid packaging, super strong adhesion, strong pulling without cracking.

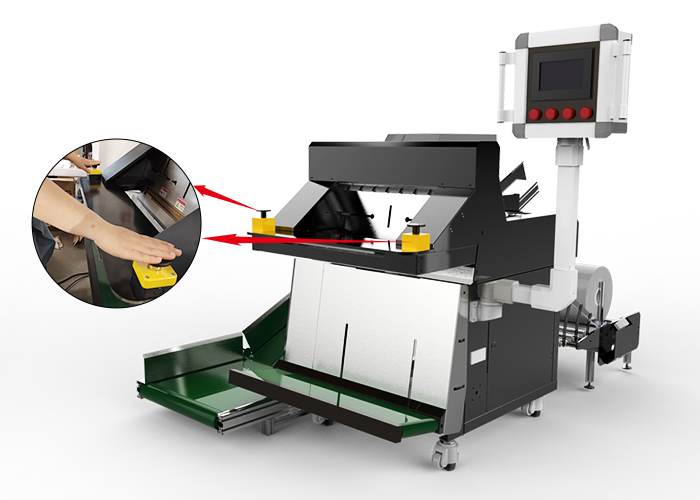

Safety

In-depth industry, understand user operating habits, establish a complete alarm mechanism and a good human-computer interaction method for safety hazards.

Double-button start switch

When starting the machine, you must press both switches with both hands to ensure that both hands are not in the working area when the machine is working, effectively avoiding accidental injuries.

Intelligent protection

The grating protection system monitors the working area in real time to ensure safe operation.

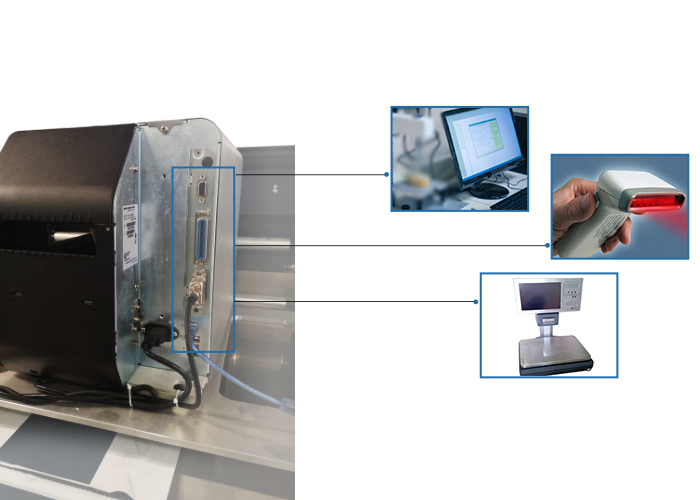

Convenient

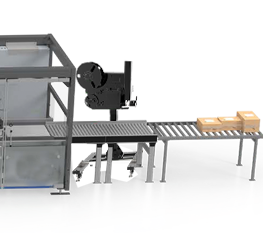

Strong expandability:

It can be connected to devices with Ethernet ports, USB interfaces, parallel ports, and serial ports, such as scanners, weighing machines, computers, etc. to achieve data synchronization, effectively avoiding wrong shipments.

Real-time synchronization with external devices

Print various QR codes, barcodes, patterns, text, numbers, etc.

Flexible movement

1.5 cubic volume, can be moved at will and fixed safely;

Scalar size, focus on the Forma wheel;

Fix the screw, gently rotate, and fix it safely without moving.

High adaptability

The lateral conveyor belt can be freely adjusted in height to support bags of different lengths, so that the bags are evenly stressed and the seal is flat.

Adjustability

The position of the trough limit rod can be freely adjusted.

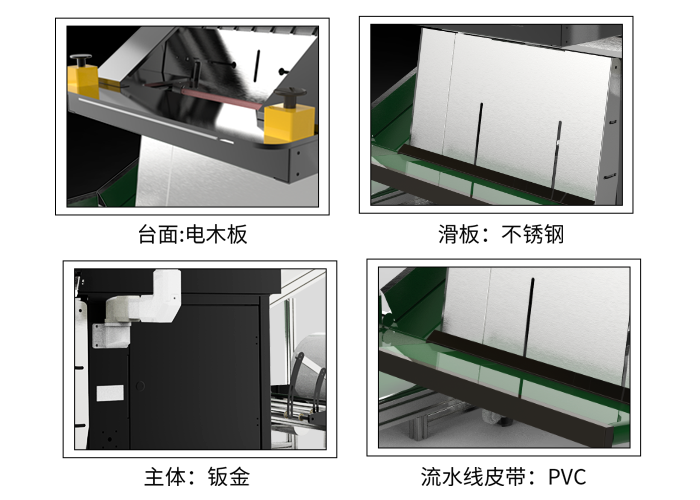

Details display

Pay attention to details, and the craftsmanship is revealed

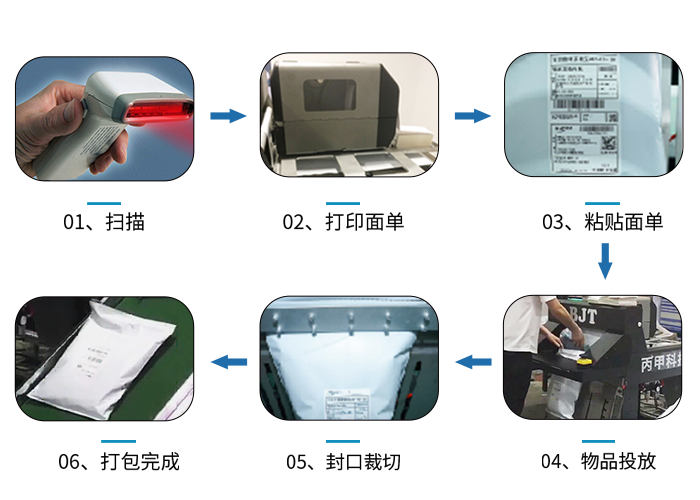

Operation process

Efficient

600 bags/hour;

Stable

7*24 hours work without error;

Safety

Grating protection system;

Convenient

Flexible movement in 1.5 cubic space.