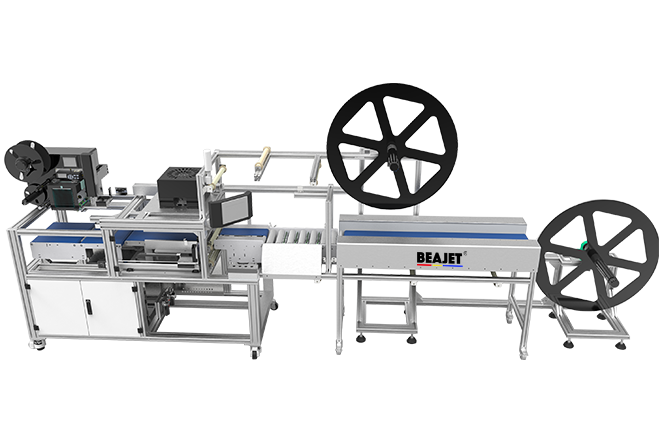

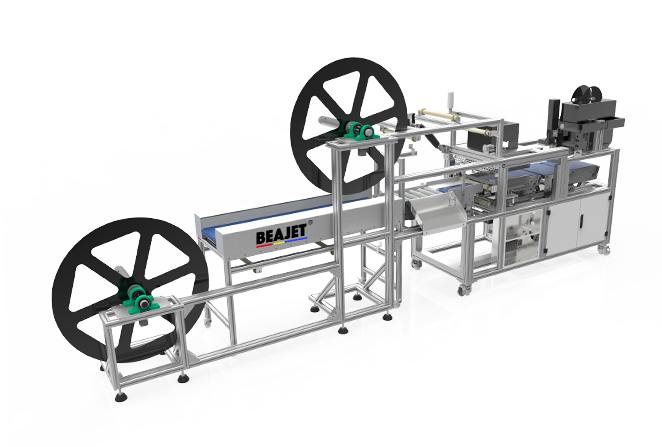

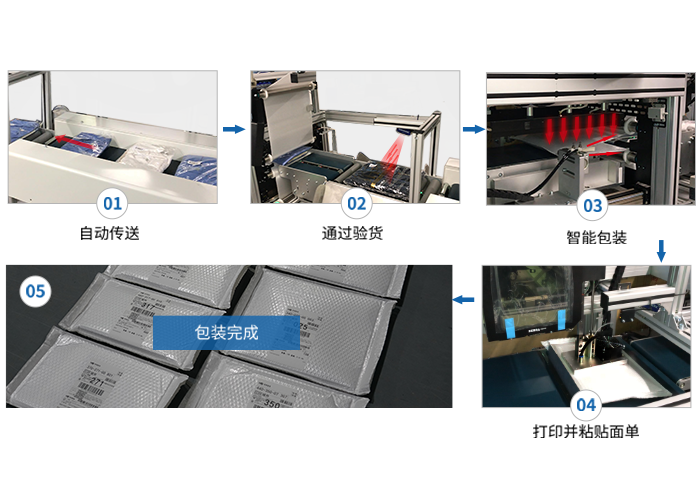

Protective Automated Mailer System:

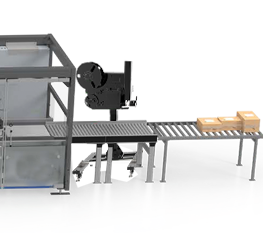

the perfect solution for e-commerce packaging, it is the integration of packaging, express label printing and application, and packaging transmission, saving labor and improving packaging efficiency.

Acceleration control system, smoother transmission

When the machine starts and stops, different accelerations can be controlled to ensure the smooth arrival of the product

Intelligent inspection

High efficiency, labor saving, no mistakes

Position self-correction

Effectively avoid improper product placement, resulting in waste of packaging materials; and abnormal machine operation

Intelligent packaging material control, never waste 1cm of material

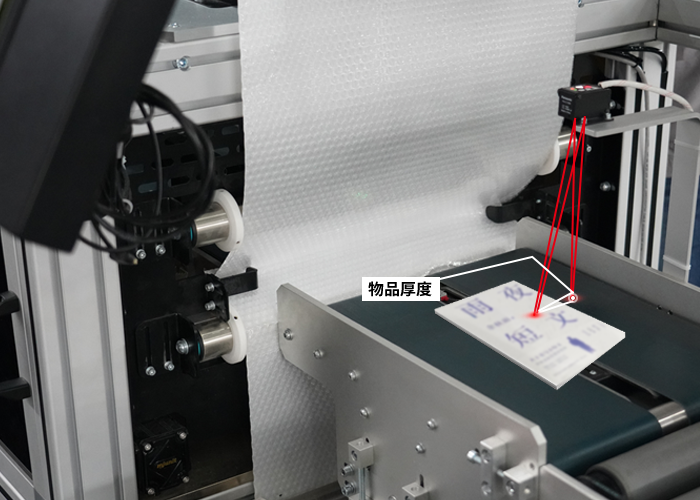

Thickness measurement:

Laser sensor, based on the principle of light beam reflection, accurately measures the thickness of the object, with an accuracy of up to

0.1mm (equivalent to the thickness of ordinary A4)

Length measurement:

The sensor accurately measures the length of the object based on a unique algorithm, and automatically adjusts the power to solve the measurement problem of black objects

Precise film drawing:

PLC calculates the optimal film length based on the size of the object, and the film drawing robot accurately pulls out the material to complete the packaging

Original technology creates fine products

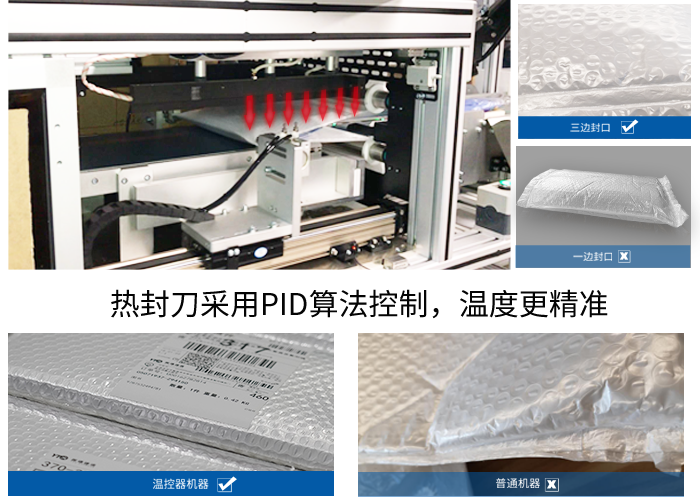

Auxiliary pressing device to remove excess air from the bag, the bag is flat, and the sealing is easier

Original three-side sealing technology, uniform force, tight sealing

The heat sealing knife is controlled by PID algorithm, and the temperature is more accurate

Cutter self-protection function

When non-film items appear at the cutting edge, the magnetic control switch accurately determines the foreign matter through information sampling, immediately stops cutting and lights up the alarm information light; while protecting itself, it effectively protects the product

Mechanical safety door Make safety more thorough

Mechanical safety door switch avoids unnecessary injuries and protects the machine from interference from external objects during operation

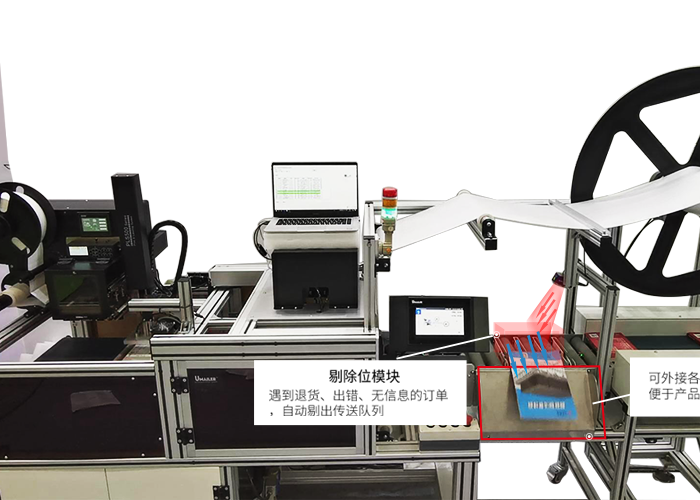

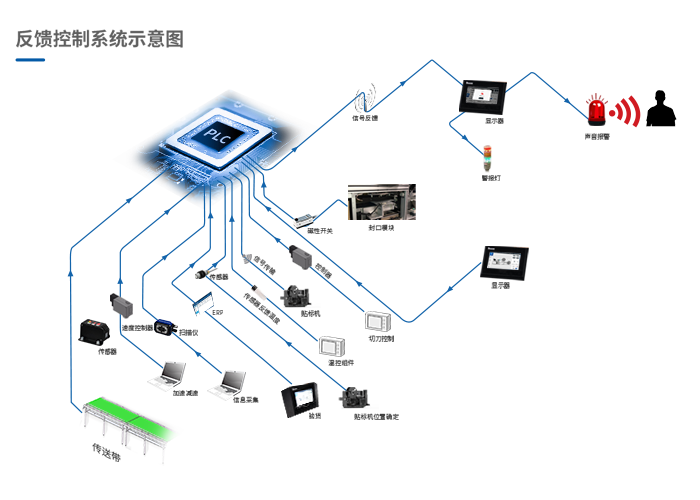

Perfect fault feedback system

Each operation process and interface is equipped with sensors to monitor the working conditions of each link in real time and synchronize information to PLC. PLC commands the orderly operation of the entire machine based on a unique algorithm. When a fault occurs and cannot be handled by itself, a prompt box will pop up to request the user to solve it and issue a red alarm

Support customization

The packaging materials are pearlescent bubble film, co-extruded film, kraft paper, solid and non-explosive items are all acceptable. Currently, it is mainly used in: textiles and clothing, stationery and books, facial masks, five-style; if you have any needs, you can contact the customized system at any time